| DIO, Finding the Innovation in Surface Processing in ‘UV Implant System’ | 2019-03-15 | 3098 |

|---|---|---|

|

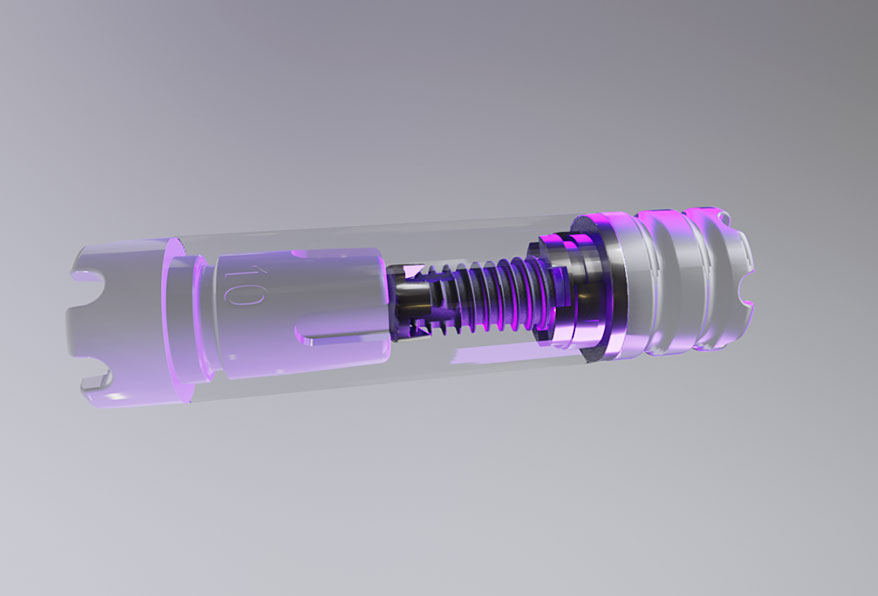

DIO, Finding the Innovation in Surface Processing in ‘UV Implant System’   Expected to become the foremost leading next generation surface processing method. The ‘UV Implant System’ that DIO, Corp. (CEO Jin Baek Kim), a leading company in digital dentistry, has ambitiously launched as the result of 7 years of intensive research has been drawing enormous attention of the relevant industries. It is anticipated to become the foremost leading next-generation surface processing method in the forthcoming years. Until now, the extensive range of research has been executed actively on the controlling of the roughness of the titanium surface and bio-activation in order to expand the scope of applications and to increase the success rate of dental prosthesis treatments using implants. Currently, SLA (sandblasted with large-grit and acid etching) methods that sequentially execute sandblasting and acid etching have been the most-widely-used surface processing method in clinical settings on the basis of its high success rates. Such SLA surface processing methods display blood-friendly aspects by forming thin oxidization layers on the titanium surface in the acid treatment process at high temperatures. However, as time passes, carbon in the air adheres to the titanium surface, which transforms from hydrophilic to hydrophobic in nature. This is an inevitable biological aging phenomenon of the titanium surface and becomes the cause for degradation of its blood-friendliness. DIO, as the result of having concentrated all of it capabilities on the improvement of the biological functions of titanium, which were limited due to such inevitable biological aging phenomena of the titanium surface, developed the ‘UV Implant System’, thereby generating innovation in the surface processing technology. ‘UV Implant System’ is a surface-processing system that enables the surface to be equipped with ultra-hydrophilic characteristic by removing the adsorption of a diverse range of organic impurities such as hydrocarbon substances on the hydrophobic titanium surface through optical irradiation by using UV on the implant surface. It is recognized as the next-generation surface treatment method with all the advantages of the titanium implant surface processing methods for dental application researched for execution in the procedural unit until now and the advantage of acquisition of hydrophilic characteristic beneficial in osseointegration. The beneficial effects of dental implants processed with UV ray were confirmed through numerous relevant literatures including those on in various in vitro and in vivo experiments including those by the team of Professor T. Ogawa of College of Dentistry of UCLA in the USA. In summary of the research results, UV treated titanium displayed the results of regeneration of bone tissues by promoting the adhesion, proliferation, and differentiation of osteoblasts, and increasing the initial fixation strength and osseointegration. In addition, the ‘UV Implant System’ of DIO maximizes the hydrophilic effects if the UV ray is irradiated for 15 minutes prior to the implant surgery. This received evaluation that the system has overcome the limitation of the need to irradiate with UV for prolonged periods of time (several tens of hours) in the past in order to achieve the effect of maintaining the ultra-hydrophilic state in the past. Mr. Sang Wook Lim, an executive director of DIO, commented that, “it is anticipated that the ‘UV Implant System’ will become an important factor in determining the success of implants through their ability to achieve quick osseointegration. In addition, with the launching of a further-evolved ‘UV Implant System’ this year, there will be a rapid increase in the number of dental hospitals adopting this system,” and that, “although I am not at liberty to disclose specific details, you can look forward to seeing out next solution achieved through intensive efforts towards innovation, which are sure to lead the next-generation of dental technologies.” |

||

| NextDIO, Operating ‘DIO Digital Academy’ in Earnest | PreviousDIO, Held a Commemorative Event for Its 31st Anniversary | |